A proficient apparel manufacturing company in Bangladesh

Always think differently with tremendous value

Always think differently with tremendous value

Always think differently with tremendous value

Norban Group At A Glance

Norban Group has started its journey in 1990. Norban is a leading apparel manufacturer and exporter of Bangladesh. It has full vertical setup with state of the art machines in knitting, dyeing, garment production, printing, and embroidery and laboratory facility. Norban Comtex LTD and Horn Bill Apparel LTD is the circular knit production unit with complete vertical set up and Trend Force LTD is the flat knit production unit of Norban group. Beside Apparel business.

Our Company

Facilities

At Norban Group, sustainability and responsibility are at the heart of everything we do. Our five state-of-the-art production facilities exemplify our commitment to ethical practices, environmental stewardship, and innovation. Each facility is designed to minimize environmental impact while maximizing quality and efficiency, ensuring that our operations not only meet but exceed global standards.

We have highly qualified in-house research and development team that works with dedication to cater the demands of fashion industry across the globe.

At NCL, total customer satisfaction is our goal and we realize that our clients’ needs are simple. They want quality goods shipped as promised and on time.

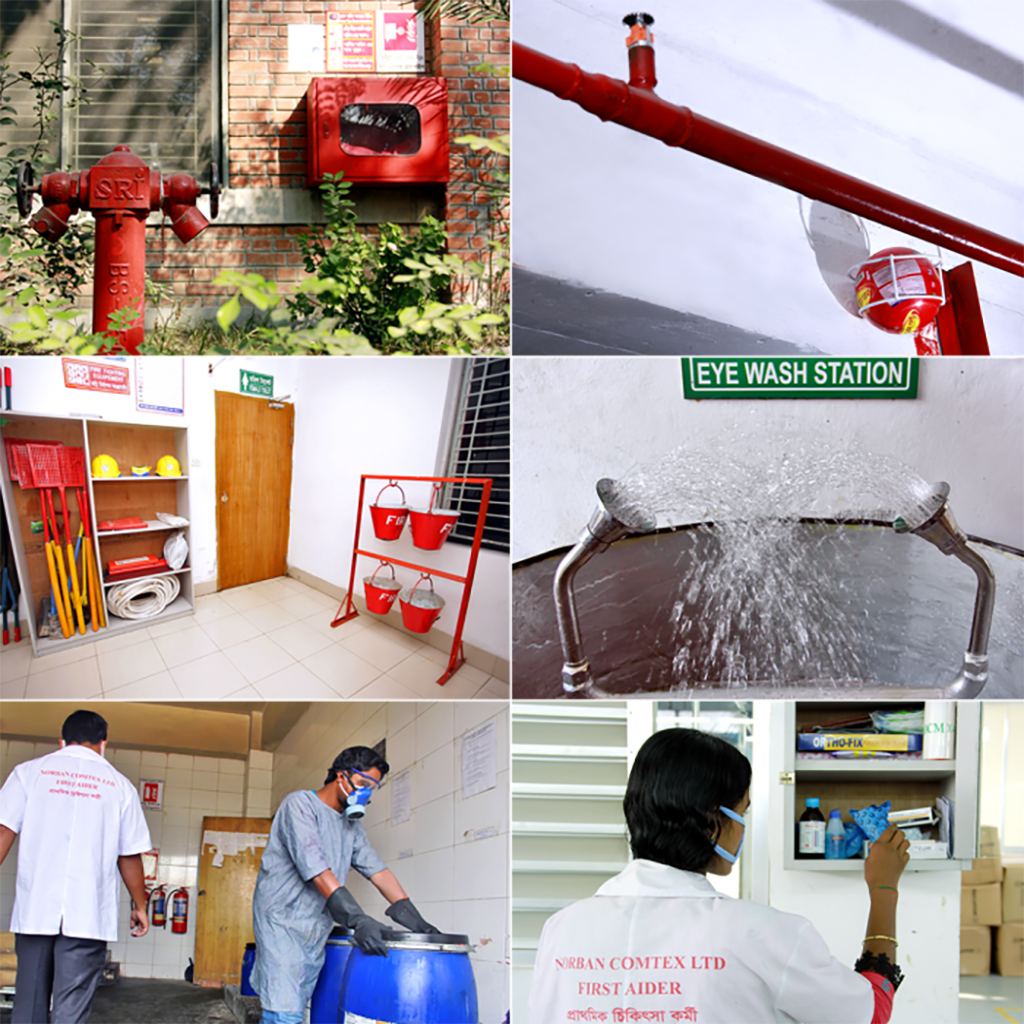

Safety measures are precautions and activities that are taken to reduce the risk of human health-related issues. They are important because they keep people safe and healthy. Here are some examples of safety measures.

Norban (CSR) Coprporate Social Responsibility is the continuing commitment by industy to behave ethically and contribute to economic development.

Norban Group Trusted supplier of high standard garments to renowned brands in Europe, UK, USA, Canada, Australia and many other countries.

Connect Norban

Join us to make a positive impact on each other and the world.

Copyright © 2024 Norban Group Companies | All Rights Reserved.